行业用途:

适用于铝扳、不锈钢板切割、镂花;幕墙切割;各类石材雕刻及切割:墓碑雕刻加工;石墙雕刻,石材牌坊,门楼雕刻;PVC/PP板切割,高精度手板,电子治具三维加工:并可加工其他_切非金属材料(如各种木材,塑胶,合成板,亚克力等)

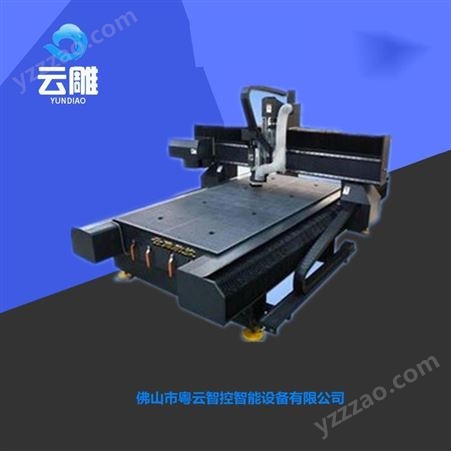

特点:

1、床身为T型钢支架,采用满焊工艺并经振动时效处理,能确保机器在高速运作时不抖动,不断刀,产品加工面高度光滑

2、X,Y,Z轴采用中国台湾上银高精度双螺母丝杆,导轨均为原装中国台湾上银方轨。加工精度高,噪音小,使用寿命长;

3、大功率恒扭矩主轴,轴承大,转速高,切削量大,且电机不易受损;

4、原装正版电脑操作系统,反应灵敏,稳定性高,且操作简单方便。

机器型号 YD-1325

平台尺寸 1300*2500mm

雕刻范围 1300*2500mm

Z轴行程 180mm

进料高度 200mm

机体配置 10mm厚T型钢支架,满焊+振动时效工艺

台面配置 50mm铸铁台面,CNC加工

Z轴挂板 U型铸铁,CNC加工

Y轴侧壁 钢结构,CNC加工

床身 10mm钢结构,CNC加工

X轴拖板 全铸铁,CNC加工

横梁 10mm钢结构,CNC加工

床支架 6mm钢结构,CNC加工

钣金 2mm厚,烤漆

吸附方式 压板

X,Y运行配置 中国台湾上银2510C3级丝杆

Z运行配置 中国台湾上银2510C3级丝杆

导轨配置 中国台湾上银25HG方轨

定位精度 ±/300mm

主轴转速 0-24000(r/min)

Y轴双驱动 日本安川850W伺服电机

X,Z轴驱动 日本安川750W伺服电机;Z轴带抱闸

运动控制 中国台湾新代6MA系统人机界面

雕刻指令 G Code、U00、mmg、nc

空程速度 0-20000mm/minute

加工速度 0-15000mm/minute

分辨率 /Pulse

刀具直径 、4mm、6mm、8mm、10mm、

主轴功率 9KW恒功率主轴,水冷

变频器 深圳四方牌恒功率

冷却系统 水泵

实际重量 2800kg

不锈钢水槽 2mm

机床电源 380V50HZ±10(内置开关电源)

电箱配置 配对刀仪手轮,人机界面电控箱

运行方式 底盘动

Features:

1, the bed for the T-shaped steel bracket, the use of full welding process and vibration aging treatment, to ensure that the machine does not shake at high speed operation, continuous knives, the product processing surface is highly smooth

2, X, Y, Z axis using silver on the silver high-precision double nut screw, rails are original Taiwan silver side rails. High precision, low noise, long service life;

3, high-power constant torque spindle, large bearings, high speed, large amount of cutting, and the motor is not easy to damage;

4, the original genuine computer operating system, responsive, high stability, and easy to operate.

Machine model YD-1313

Platform size 1300 * 1300mm

Engraving range 1300 * 1300mm

Z axis travel 180mm

Feed height 200mm

Body configuration 10mm thick T-shaped steel bracket, full welding + vibration aging process

Countertop configuration 50mm cast iron countertops, CNC machining

Z-linked plate U-type cast iron, CNC machining

Y-axis sidewall steel structure, CNC machining

Bed 10mm steel structure, CNC machining

X-axis trailer full cast iron, CNC machining

10mm steel beam, CNC machining

Bed frame 6mm steel structure, CNC machining

Sheet metal 2mm thick, paint

Adsorption mode platen

X, Y operation configuration Taiwan silver 2510C3 grade screw

Z operation configuration Taiwan silver 2510C3 grade screw

Rail configuration Taiwan silver 25HG square rail

Positioning accuracy ± / 300mm

Spindle speed 0-24000 (r / min)

Y-axis dual drive Japan Anchuan 850W servo motor

X, Z axis drive Japan Yaskawa 750W servo motor; Z axis with brake

Motion control Taiwan new generation 6MA system man - machine interface

Engraving instructions G Code, U00, mmg, nc

Empty speed 0-20000mm / minute

Processing speed 0-15000mm / minute

Resolution / Pulse

Tool diameter ,4mm, 6mm, 8mm, 10mm,

Spindle power Constant power spindle, water cooled

Inverter Shenzhen Quartet licensing constant power

Cooling system water pump

Actual weight 2800kg

Stainless steel sink 2mm

Machine power supply 380V50HZ ± 10 (built-in switching power supply)

Electric box configuration with knife knife hand wheel, man-machine interface control box

智能化打孔攻丝机发展前景及配置说明

智能打孔攻丝机的出现,改变了传统的打孔模式,传统工艺是采用手电钻和磁力钻相结合的手工做法,无法实现现代工艺发展需求,其劣势主要表现在人力成本高,商家无法承受,加工精度差,无法按标准交货,加工速度慢,无法按时完成有效订单。智能化打孔攻丝机解除了以上传统手工操作的弊病,利用CNC数控智能技术,将所需加工流程工艺集成在一条生产线上来执行,确保了加工速度、加工精度及大量人工成本,选择智能化钻攻雕铣机是现代金属精加工行业老板制胜的法宝。

1:双工序操作,当机头1加工完毕时候,该机头将自动退出可以安装工件,机头2自动开始加工工,循环往复停止,确保加工速度,提高工作效益。

2:系统采用一拖二结构,一个机头带动两主轴,同时加工两个工件,加工起来得心应手事半功倍。

3:云雕智能化钻攻中心采用日本三菱伺服系统,加工速度更快且更。

4:为方便操作系统配置了手轮,操作起来更加简单快捷。

5:为设备正常运行,系统配置了专业循环冷却系统,确保主轴的正常运行,附带的自动注油泵系统更加了传动系统的保护,使得导轨丝杠一直处于润滑油保护状态

6:为设备精度处于以下可执行标准。所有丝杠导轨均采用进口品牌,更加确保了加工精度及设备的使用持久度。

7:系统采用中国台湾新代钻孔攻牙设备,了其加工质量、精度、速度及可靠性

8:加攻速快过加工中心,每天可加工15000个工件

Intelligent drilling tapping machine development prospects and configuration instructions

The emergence of intelligent drilling tapping machine, changing the traditional punching mode, the traditional process is the use of hand drill and magnetic drill combined with the manual approach, can not achieve the development of modern technology needs, the main weakness in the high cost of manpower, businesses can not Bear, poor processing accuracy, can not be delivered according to standard, processing speed is slow, can not be completed on time effective order. Intelligent drilling tapping machine to eliminate the above shortcomings of the traditional manual operation, the use of CNC digital control technology, the required processing process integration process in a production line to ensure that the processing speed, processing accuracy and a large number of labor costs, Drilling and Engraving Machine is a modern metal finishing industry boss to win the magic weapon.

1: double operation, when the machine 1 processing is completed, the machine will automatically exit the workpiece can be installed, the machine head 2 automatic processing workers, recycling never stop, to ensure processing speed and improve work efficiency.

2: the system uses a drag two structure, a head to drive the two spindles, while processing two parts, processing up to be more handsome effort.

3: cloud of intelligent drilling center using Mitsubishi servo system, processing faster and more accurate.

4: to facilitate the operating system configuration hand wheel, the operation is more simple and quick.

5: In order to ensure the normal operation of the equipment, the system is equipped with a professional circulation cooling system to ensure the normal operation of the spindle, with the automatic oil pump system to ensure the protection of the transmission system, making the guide screw has been in the state of lubricating oil

6: In order to ensure the accuracy of the equipment below executable standards. All screw guide rails are imported brands, more to ensure the accuracy of the use of equipment and durability.

7: The system uses Taiwan's new generation of drilling tapping equipment to ensure its processing quality, accuracy, speed and reliability

8: plus attack speed faster than the processing center, can be processed 15000 a day workpiece

The company is specialized in the development of intelligent drilling and engraving and milling equipment. The products are widely used in communication wire, aluminum alloy TV frame, curtain wall cutting punching tapping, aluminum veneer cutting and industrial product processing industry.

所有评论仅代表网友意见,与本站立场无关。